New method shortens the processing of fibre parts

Short fibre-reinforced thermoplastic injection moulded parts are increasingly being used in place of steel or aluminium. Germany’s Fraunhofer Institute for Structural Durability and System Reliability LBF has developed a method to take into account the fibre orientation of short fibre-reinforced injection moulded parts, even at stages where there are still no components, such as prototypes. This phenomenological calculation concept is expected to close a significant gap in the design cycle of these moulded parts.

Depending on the level of detail required, the new procedure can be regarded as an independent solution for component design or as an upstream supplement for integrative simulation.

Typical applications for short fibre-reinforced thermoplastic injection moulded parts include their usage in the automotive or aerospace industries. In the automotive industry, in particular, where large quantities are required in the shortest time frames, the injection moulding process represents an efficient manufacturing process of plastics, also allowing for high design flexibility. However, predicting fibre orientation, which is determined by the process, material and dimensions being used, still presents a major challenge. This concept is still at the cutting edge of current research.

One method of incorporating fibre orientation into the design of corresponding shaped parts is integrative simulation. This makes it possible to transfer relevant process information into an associated structure simulation using a suitable interface and therefore predict component behaviour. However, the individual steps of integrative simulation must all be consistently validated and calibrated using experimental data. This means that process parameters and tool geometries must be known and real mouldings must be available. Consequently, this concept is only available as of the stage of component development where prototypes can already be produced.

By contrast, the process developed by researchers at Fraunhofer LBF already takes the fibre orientation of short fibre-reinforced injection moulded parts into account at a stage where no actual components are yet available.

Unlike with fully integrative approaches, the new calculation method does not determine the fiber orientation based on finite elements but rather on shaped elements or key areas. These can be, for example, ribs, domes or flat areas.

Unlike with fully integrative approaches, the new calculation method does not determine the fiber orientation based on finite elements but rather on shaped elements or key areas. These can be, for example, ribs, domes or flat areas.

Scientists have developed a new moulding tool to asses the fibre orientation as a function of the shaped element and the angle of incidence. This offers the possibility of integrating different functional elements while maintaining the same molding base. Large and small domes and ribs were used as interchangeable inserts for functional elements. With the new tool it is possible to investigate the influence of the flow conditions by varying the angle of incidence. Thanks to the concept, further approaches can be developed in a cost-effective manner. The tool has two cavities with different wall thicknesses which can be operated independently of each other. The base of the moulded parts is a 60 x 60 mm plate.

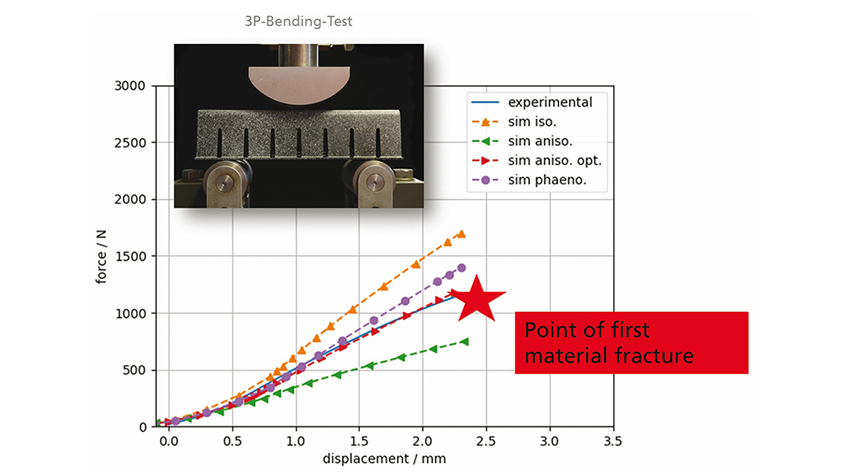

In their experimental fibre orientation analyses, the scientists in Darmstadt found a variety of distinct fibre orientations. The information necessary for the desired modeling method is derived from the second-order orientation tensor, i.e. its main orientation and degree of distribution. The information obtained can now be used to determine the anisotropy and the main direction for each layer. In this case, the number of layers can be defined as a change in the orientation distribution (suitable for the material) or as a manual specification (based on experience). An automatic analysis algorithm determines a suitable material model, for example isotropic or orthotropic, for each layer identified, as well as all necessary model parameters. For this purpose, in addition to the data from the computer, determined mechanical test data are required as an input.

This information can then be transferred to the model in the structure simulation (mapping). The method can be applied to results from injection simulations as well as to results of CT analyses.

In addition to a simplified design strategy, further application scenarios are created using an information database dependent on the shaped elements. On the one hand, the information can be used to design components in accordance with the potential stress they will be exposed to, for example, ribs in the correct positions with the optimum shape and orientation. On the other hand, it has been shown that the results can be used to optimize the fibre orientation calculation used in integrative approaches.

The results presented here were generated as part of the IGF project 18362N “Phenomenological Calculation Strategy for Short-fibre-reinforced Injection Moldings”, funded by the Federal Ministry for Economic Affairs and Energy via the AiF as part of the program for the promotion of industrial joint research and development (IGF) following a ruling of the German Bundestag.

Teknor Apex Announces NEW Monprene® TPEs

Teknor Apex Announces NEW Monprene® TPEs with 60% Post-Consumer Recycled Content, Reducing…