Teknor Apex Announces NEW Monprene® TPEs

Teknor Apex Announces NEW Monprene® TPEs with 60% Post-Consumer Recycled Content, Reducing Carbon Footprint by up to 36% while maintaining translucency for vibrant colors

Certified product carbon footprint data is available for the entire Monprene® R6 CP-10100 Series

(Teknor Apex, Pawtucket, RI USA, September 12, 2024) … Teknor Apex is pleased to introduce a new series of Thermoplastic Elastomers (TPEs), the Monprene® R6 CP-10100 series, containing 60% post-consumer recycled content; a significant added value that helps brands achieve their sustainability goals without any compromise in quality or performance. Major consumer brand owners and processors alike, have long trusted Monprene® thermoplastic elastomers (TPEs) in many consumer applications from sporting goods, lawn and garden to consumer electronics, appliances and personal care. This latest series allows designers and manufacturers to improve their environmental impact by significantly reducing the carbon footprint compared to fossil-based TPEs.

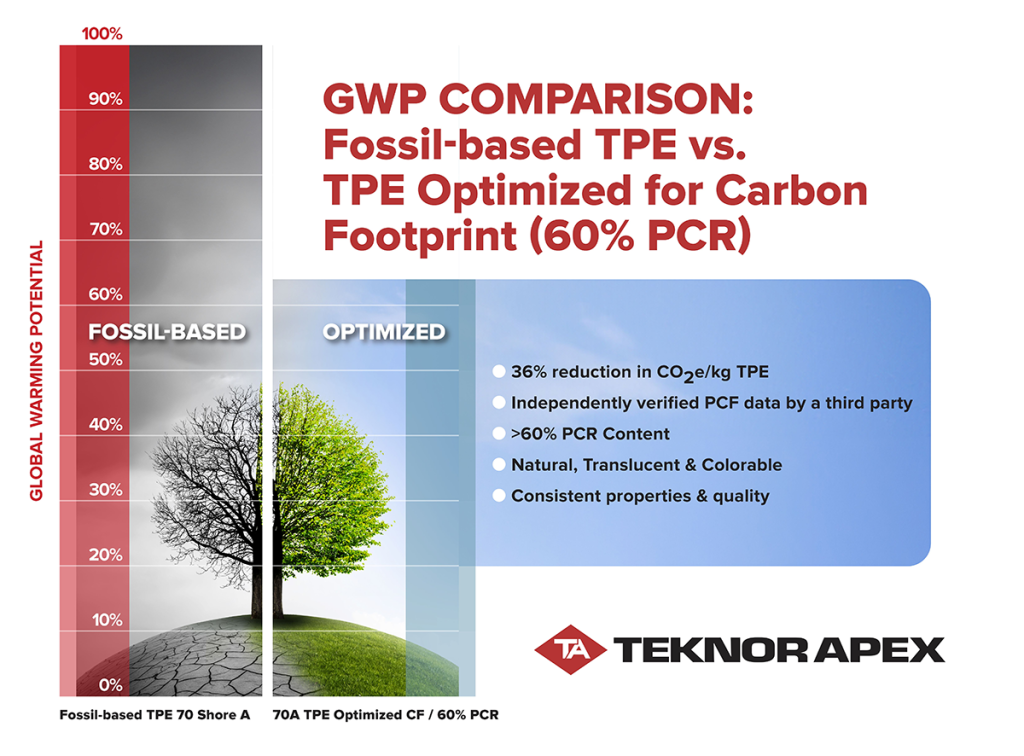

The Monprene® R6 CP-10100 series formulations have been optimized for achieving a minimum carbon footprint. For instance, the 70 Shore A grade, Monprene® R6 CP-10170, results in a reduction of 36% in CO2e/kg TPE versus a fossil-based TPE of similar hardness (see chart below). Product carbon footprint data is available for the entire Monprene® R6 CP-10100 series portfolio of products. The data has been critically reviewed by a third party to ensure compliance.

How Product Carbon Footprint is Determined

Product Carbon Footprint calculates the Global Warming Potential (GWP) attributed to a product, by quantifying the CO2e footprint using “cradle-to-gate” system boundaries – which mean from the extraction of the raw material through manufacturing of the product, to the factory gate*. Teknor Apex data is calculated according to the guidelines of the Greenhouse Gas Protocol Product Life Cycle Accounting and Reporting Standard as well as the ISO 14067 framework and has been critically reviewed. For the Monprene® R6 CP-10100 Series, the system boundaries were set to Cradle-to-Gate for Teknor Apex’s production facility in Germany. This site is currently undergoing RecyClass certification to ensure full traceability.

*(It does not include transport to the customer, further processing, use or end of life treatment.)

A Sustainable Option for a Variety of Applications

The unique feature of these materials is their high levels of post-consumer recycled content without sacrificing translucency or color, making them ideal for consumer products applications with specific color requirements. At Teknor Apex, recycled feedstocks are treated like prime raw materials and are subject to quality assurance testing and must meet relevant specifications. The post-consumer recycled content used in this Monprene® series is clean and reliable.

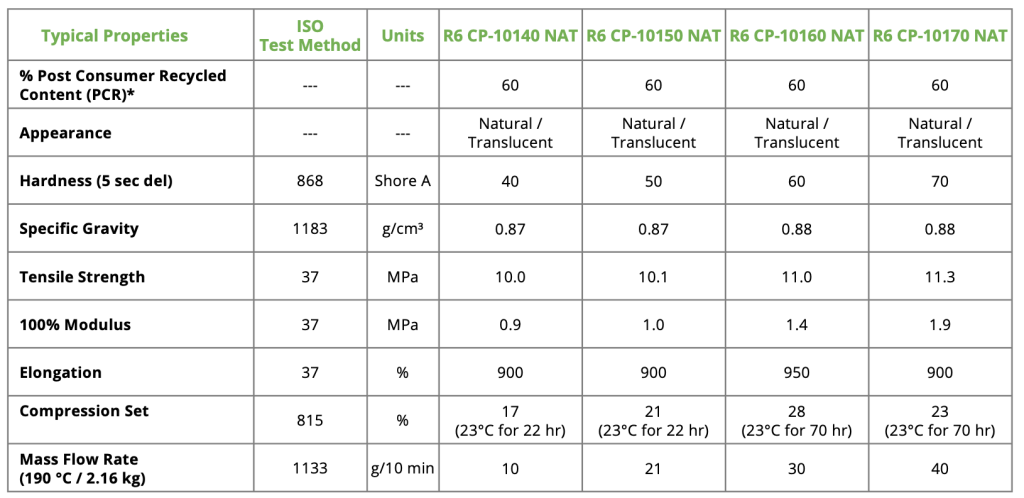

The Monprene® R6 CP-10100 series is available in standard grades from 40 to 70 Shore A and can also be tailored for a customer’s specific requirements. These grades are designed for injection molding applications, including overmolding onto polypropylene. These materials perform and process like prime TPE and are ideal for sporting goods, lawn and garden, to consumer electronics, appliances and personal care. This TPE series supports circularity and helps conserve finite resources not only by incorporating recycled feedstock, but also because the materials are still fully recyclable at the end of the product’s life.

“This unique TPE offering is an important part of our complete sustainability program. We continually look to increase the sustainability of our products, while reducing the environmental impact of our manufacturing operations. This year, in support of our sustainability goals, we are proud to report that the Germany plant converted to 100% renewable energy and reduced water usage by >50%,” said Chris Smith, Market Manager.

Monprene® R6 CP-10100 Series TPEs are RoHS compliant and manufactured at our Germany facility according to the standards of ISO-9001 and ISO 14001. For more information, please contact us at tpe@teknorapex.com

Teknor Apex is currently celebrating its 100th year anniversary in 2024, sharing its rich and enduring history of dedicated people, strong partnerships and ingenuity, that enables new product development such as this new series. Learn more about this 100th year milestone HERE.

Typical Properties | Monprene® R6 CP-10100 Series

* Percentage of Recycled Content = Mass of Recycled Material in Compound / Total Mass of Compound x 100

GRAPH CAPTION: Monprene® R6 CP-10100 Series is currently available in 40, 50, 60 and 70 Shore A, but the hardness can be tailored to specific customer requirements. The “R” prefix denotes recycled content.

About Teknor Apex.

Teknor Apex Company, a privately held firm founded in 1924, is one of the world’s leading custom compounders of plastics. Teknor Apex produces flexible and rigid vinyl, thermoplastic elastomers, engineering thermoplastics including polyamides, polymer colorants, masterbatches, esters and outdoor garden hose. The company is headquartered in Pawtucket, RI, U.S.A. and operates thirteen manufacturing facilities worldwide in the United States, Belgium, Germany, China, and Singapore.

Teknor Apex Company offers the broadest portfolio of thermoplastic elastomers (TPEs) available from a single source. The company compounds TPEs at eight locations in the U.S., Europe, and Asia under the brands: Elexar® (electrical and electronics applications), Medalist® (medical devices), Monprene® (consumer and industrial products), and Sarlink® (transportation). To learn more visit: www.teknorapex.com.

KraussMaffei showcases pioneering Additive Manufacturing solutions at formnext

precisionPrint stereolithography 3D printer show smultilaser-technology for series product…