Arburg focusing on digitalised processing in China; to maintain production in Germany

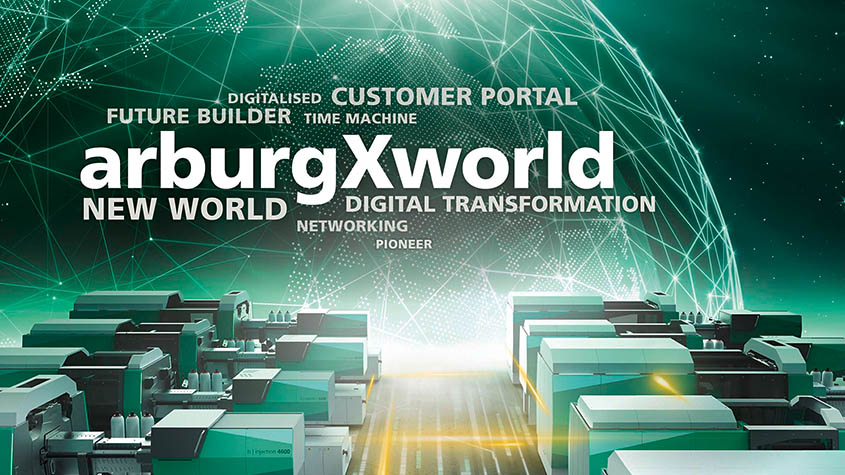

German injection moulding machine firm Arburg was for the first time present a Chinese version of its new arburgXworld customer portal at Chinaplas 2019, to be held from 21-24 May in Guangzhou, China.

Meanwhile, against the backdrop of the ongoing trade war “spat” between the US and China and challenges in trade barriers, the German machine maker is going to stick to production in Germany and not venture to China or any other country, said Gerard Boehm, Managing Director Sales, Arburg, speaking at a pre-Chinaplas conference.

However, did not rule out tweaking and customisation to suit turnkey production needs. “We already have a large store of machinery in China and are able to customise these according to client’s needs,” he said adding that the philosophy of the family-owned company is to keep production in Germany to maintain quality.

Digital assistance packages and the potential of Augmented Reality (AR) for service purposes will also be showcased as further highlights on the subject of digitalisation. The exhibited machines will be networked with the Arburg ALS host computer system, said Zhao Tong, Managing Director of the Arburg organisation in China.

The arburgXworld will be accessed by a first group of test customers in China as early as this summer, from K2019 onwards the customer portal will become available worldwide.

Arburg will bundle its digital services in this new service marketplace and gradually expand them. Once enabled, the required applications (apps) in the cloud can be used on a PC or mobile device. To mark the launch of the customer portal, there will be four apps: “Machine Center”, “Service Center”, “Shop” and “Calendar”:

The “Machine Center” app brings transparency to production and reduces organisational effort. It provides a quick overview of the machine fleet and enables central access to production-relevant documents.

The “Service Center” app can be used to start service tickets around the clock – including from mobile devices on site. Open service tickets, the current processing status and the planned deployment of service technicians are clearly displayed and can be centrally tracked.

The spare parts catalogue is a central component of the “Shop” app. Interactive navigation and clear 3D previews make searching easier. In addition, there is direct access to prices and availability.

In “Calendar”, upcoming maintenance and other tasks can be clearly displayed.

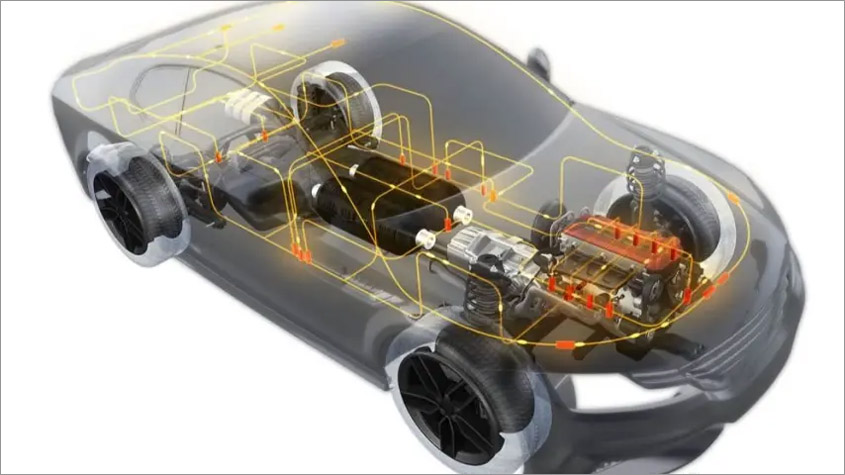

As a central component of Industry 4.0, the Arburg host computer system (ALS) enables production planning as well as complete traceability of orders and batches. Allrounder injection moulding machines, the Freeformer for industrial additive manufacturing and peripheral equipment can be easily and uniformly networked using interfaces based on the OPC UA communication platform.

At Chinaplas 2019, all Arburg exhibits are connected to ALS in this way. The host computer system records and archives all the relevant process data online and is linked directly to the company network via a PPS or ERP interface. At the exhibition stand, visitors will be able to see live how relevant process data can be recorded and archived online and how current key figures and machine statuses can be queried and displayed.

Visit Arburg at Stand A41, Hall 5.1

KraussMaffei showcases pioneering Additive Manufacturing solutions at formnext

precisionPrint stereolithography 3D printer show smultilaser-technology for series product…