CHINAPLAS: ILLIG’s new IC-RDM 73K thermoformer to make Asian debut

The focuses of presence at CHINAPLAS 2019 for ILLIG, the German leading global supplier of thermoforming systems and mold systems for thermoplastics, will be automatic roll-fed machines.

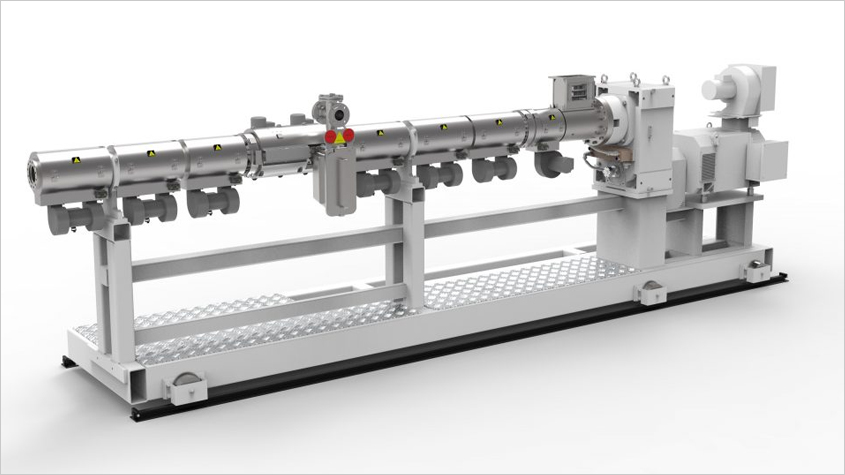

One of the highlights is the new IC-RDM 73K thermoformer which will be displayed in Asia for the first time. The machine is integrated in a fully automated production line for drinking cups made of A-PET and A-PLA.

At the same time, the IC-RDK 80 automatic roll-fed machine will be in live production on the line of an oval A-PET tray.

IC-RDM 73K: High output and quick-change system for molds

IC-RDM-K machines are designed specifically for serial production of cups in various shapes and sizes from thermoplastic material. The new IC-RDM 73K has a high output and a quick-change system for molds. Moreover, ILLIG consistently implemented the Cleantivity concept in the machine.

Compared to the IC-RDM 70K machine, the forming area of the new machine is enlarged by 23%. Subject to applications, all improvements together contribute to an up to 25% increased production.

Besides, a new, easy to use system for block change of molds reduces tool installation and removal times by more than 50%, which means the change can be performed in less than 60 minutes.

At the show, drinking cups will be produced on the line using a 32-up mold, at a speed of 50 cycles per minute. The cups are made of A-PET and A-PLA films (0.7 mm thick). The machine on stage is combined with an in-line PH 73 stacking machine which can be variably equipped with different discharge options.

Machines of the IC-RDM-K series are also frequently used as in-line systems with pre-linked extruders, e.g. for large-volume production of drinking cups in quantities of millions. The ILLIG IC supports the aspects relevant for large-volume production. It includes modules for general process optimization, high productivity and availability as well as minimization of operation costs.

IC-RDK 80: High availability and easy operation

With IC-RDK series, ILLIG developed a forming and punching technology suitable to achieve excellent part quality and reproducibility of rays and hinged packs, used for protection of food during transport and as sales packs. The machines feature high availability and easy operation.

Heated materials are formed by means of pre-stretcher and compressed air, and the part is punched out of the material in the same cycle. Thanks to this method, parts can be manufactured without punching mismatch in the rim area, and thus automatic pack processing is improved.

The company will be showcasing the IC-RDK 80 automatic roll-fed machine with live production on the line of an oval A-PET tray made of a 0.4 mm thick film with A/B stacking using a 10-up mold, at a speed of 50 cycles per minute.

The variety of benefits

ILLIG thermoforming production lines offer various benefits. Thin-walled packaging means a tangible savings in raw materials and thus lower production costs. The high working cycle results in a high output of flawlessly formed parts, and the thermoforming molds can be exchanged quickly and easily.

With the unique 360° packaging development Pactivity, from the idea to the final packaging and complete production system, the company provides customers with a 360° custom-made packaging solution from a single source.

Moreover, with the Cleantivity concept ILLIG has consistently pursued a strategy of increased productivity in thermoforming, optimizing quality time and clean production with high machine availability.

ILLIG also helps customers to position their flagship products produced on its IML-T systems. Thanks to the realization of single-material packaging (decoration and packaging in the same material), recycling is simplified and the products are more sustainable.

KraussMaffei showcases pioneering Additive Manufacturing solutions at formnext

precisionPrint stereolithography 3D printer show smultilaser-technology for series product…