Green Materials: Sabic’s Elcrin upcycled PBT

Chemical firm Sabic has introduced its LNP Elcrin iQ portfolio of polybutylene terephthalate (PBT) compounded resins derived from recycled polyethylene terephthalate (rPET) to support the circular economy and help reduce plastic waste. products also offer a smaller cradle-to-gate environmental footprint than virgin PBT resin, as measured by Cumulative Energy Demand (CED) and Global Warming Potential (GWP).

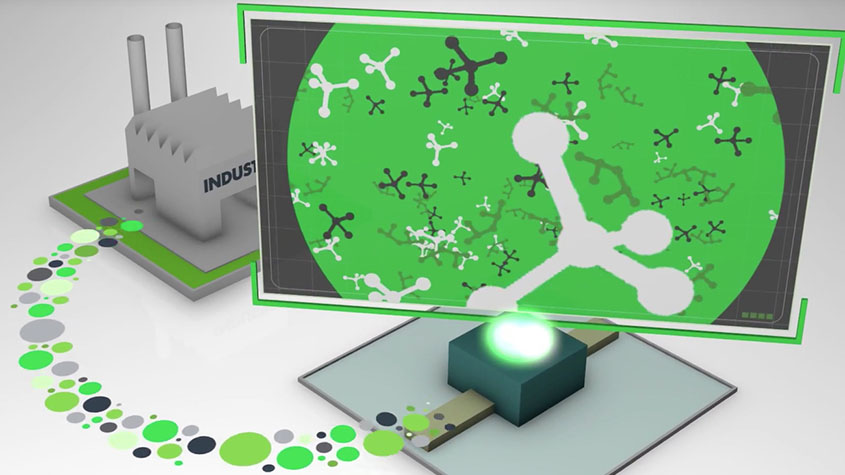

The Elcrin iQ compounds and blends are based on upcycled iQ PBT resins, a proprietary Sabic technology. This technology overcomes some of the limitations of mechanical recycling by using chemical processes to depolymerise PET bottles and other PET waste into their precursor chemicals, purify them and then use them to create new PBT resin. The technology can deliver performance and processing benefits such as good chemical resistance, colourability, high flow for faster throughput and flame retardance (FR).

The new resin is a drop-in solution for virgin PBT and other conventional PBT materials, making it easier for manufacturers to make their products more sustainable. It is also able to reduce the energy and carbon footprint of the material by up to 61% and 49%, respectively (The original peer-reviewed life cycle assessment study was completed by Sabic in 2011. The results are being reviewed and updated based on current models, with expected completion and peer-review in 2019, says Sabic).

Further, each kilogram of the resin uses up to 67 post-consumer PET water bottles (0.5 l).

The portfolio is also said to offer multiple options, including glass and mineral-reinforced grades and non-halogenated FR and UV-resistant formulations. Some of the LNP iQ grades have even have the potential to achieve compliance with US Food & Drug Association (FDA) food contact regulations.

Potential applications for these new polymers include internal and aesthetic components for consumer electronics, automotive connectors, and housings for medical devices.

KraussMaffei showcases pioneering Additive Manufacturing solutions at formnext

precisionPrint stereolithography 3D printer show smultilaser-technology for series product…