Kautex to unveil new 6-layer extrusion head for packaging applications at CHINAPLAS

At CHINAPLAS this year, Kautex will present a blow molding machine with a newly developed 6-layer extrusion head which was jointly developed by German and Chinese engineers at the company.

The new 6-layer extrusion head can be used to produce multi-layer hollow plastic containers with a volume of between 500 and 1500 ml. These are mainly used for packaging applications in the food sector.

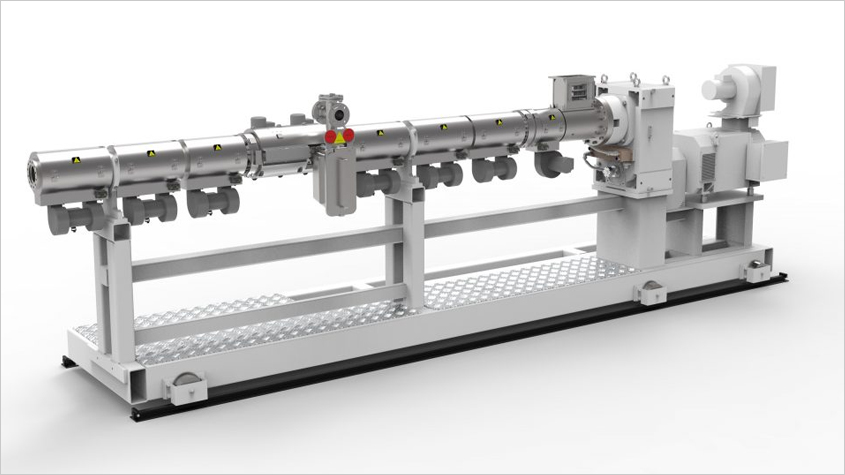

In live operation on a 3rd-generation KCC10S blow molding machine, visitors of the show can see the new extrusion head’s functionality and performance. This machine range, which is made in China, is used as a laboratory machine at all Kautex technical facilities around the world.

Enables production of multi-layer bottles

At the show, the KCC10S MK3 will produce a 1000 ml 6-layer milk bottle. The single station machine has a CP50 extrusion head, the first 6-layer extrusion head for consumer packaging made in Kautex’s Chinese factory in Shunde.

CP50 heads are compatible with machines of Kautex’s KCC and KBB series, and in some cases can also be retrofitted on other machines. The heads of this new series have a minimum center distance of 140 mm.

Mastering production processes on simulator

As well as exhibiting its KCC10S MK3 machine, Kautex will also demonstrate its virtual training simulator at CHINAPLAS. These virtual machines are used in the same way as flight simulators to train employees in the various production processes on Kautex machines.

As introduced, the virtual machines are now available for the KBS, KBB and KCC series. The compact work stations are equipped with a powerful computer simulator, two monitors, and a projector. They are used for training and demonstration purposes at the Kautex locations in Bonn (Germany), Shanghai, Shunde (China) and New Jersey (USA).

The virtual machines enable employees to be trained on Kautex machines in realistic conditions but without the risk of causing any damage due to incorrect operation, and without consuming any materials. They are mobile, can plug into any standard domestic electrical socket, and are available to rent for customers for training purposes.

KraussMaffei showcases pioneering Additive Manufacturing solutions at formnext

precisionPrint stereolithography 3D printer show smultilaser-technology for series product…