Sonderhoff demonstrates Formed In-Place (FIP) sealing technology at Auto Shanghai

At the 18th Shanghai International Automobile Industry Exhibition (Auto Shanghai 2019, April 18 – 25), the Suzhou based Sonderhoff (Suzhou) Sealing Systems presents their products and services to the automotive industry in China.

The German based Sonderhoff group, part of Henkel AG & Co. KGaA, is one of the world’s leading system suppliers for innovative sealing technology from a single source. The System3 concept from Sonderhoff comprises material and machine as well as contract manufacturing for sealing, gluing and potting of components.

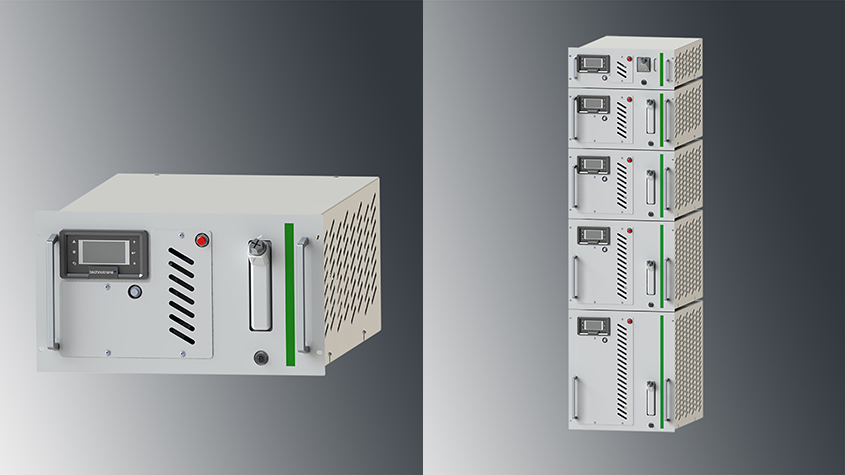

The visitors of the show fair can experience the precision of the 3 component DM 403 mixing and dosing machine from Sonderhoff during the live demonstrations.

Sonderhoff is process specialist for automated sealing solutions. It comprises the automated material application on parts of small to large series productions using the formed in-place (FIP) sealing technology.

“FIP has established as state-of-the-art technology for the sealing, gluing and potting of components, an efficient, precise and economical production method in various industries”, says Santiago Jove, the new managing director of Sonderhoff (Suzhou) Sealing Systems.

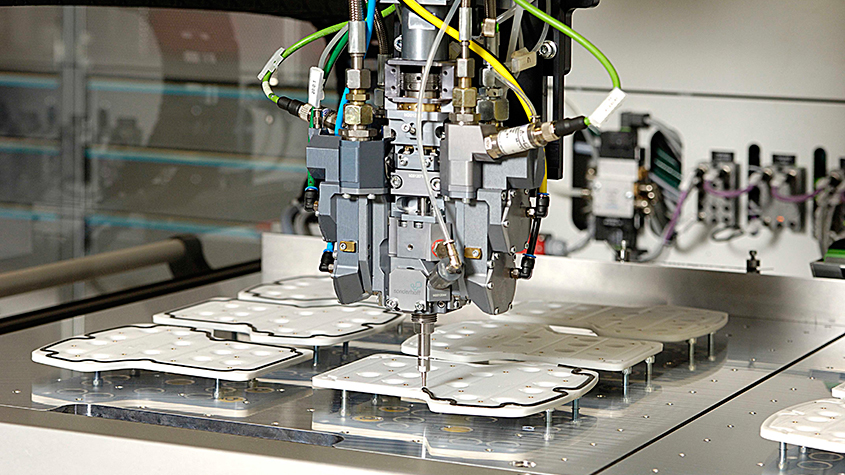

The FIP sealing technology is especially beneficial for the highly synchronized series production in making of cars. The parts are processed with the very precise linear robots of Sonderhoff’s mixing and dosing machines. Six axis robots for the part handling are used for complex 3D component geometries.

When it comes to precise material dosing, accurately applied to the parts’ contour, the advantages of FIP become very clear. Due to different lengths and diameters dosing nozzles reach into remote areas of 3 dimensional parts so that foam sealant, glue or potting can be applied precisely.

“The FIP sealing is also a very economical production technology. It can save time and money. The liquid gasket material is 100% utilized and there are no punching or scrap losses as with the classical pre-fabricated moss rubber seal. Thanks to the curing of the material systems at room temperature, there are no investment and energy costs for tempering ovens,” explains Peter Wang, general manager of Sonderhoff in Suzhou.

The liquid applied Fermapor K31 foam system cures to a soft foam seal under room temperature >>in situ<< direct on the component. And because it is applied liquid, the beginning and end of the seal can flow into each other, creating a seamless seal. The components are thus protected from rain, ice and snow, cold, heat, dust and wind, but also mechanical influences.

Making the FIP process added value

The dosing machines and material systems from Sonderhoff are optimally matched to each other. Depending on customer requirements, different curing and tack-free times of the material systems from Sonderhoff are individually adjustable. This makes the manufacturing processes even more efficient, and downstream processes, right through to final assembly, can start earlier.

It is an extra benefit, if automatic FIP applications are reliably reproducible in large numbers subject to the required zero fault tolerance in the automotive industry. Therefore, Sonderhoff uses for its dosing systems CNC-controlled linear robots which move the mixing head over the component contour very exact at different speeds for material dosing. They reach a repeating accuracy of 0.1 mm.

For complex component geometries in series production six axis robots are used. All information relevant for the quality of safe engineering, material and the process are automatically recorded by the Sonderhoff mixing and dosing systems, accessible at any time.

Wide range of material properties

The foam sealing, adhesive and potting systems from Sonderhoff are very versatile for the use in the car industry. The polyurethane potting systems Fermadur are applied in various application areas, from surface coating to filter gluing and encapsulating electronic car components, such as connector plugs, relays, transformers, condensers and sensors.

However, decisive for constant quality of foam sealing, gluing and potting are the right choice of raw materials, excellent workmanship as well as security and accuracy of the dosing machines. This offered by Sonderhoff in Suzhou ensures a very economic, precise and safe application process of the materials on the components.

KraussMaffei showcases pioneering Additive Manufacturing solutions at formnext

precisionPrint stereolithography 3D printer show smultilaser-technology for series product…