Automation: Bringing automation barriers down with end-of-arm tooling

In this article, James Taylor, General Manager, APAC of OnRobot, explains how intelligent endof- arm tooling (EOAT) is helping manufacturers deploy robots. EOAT changes the game with its revolutionary features and functions, making automation easier to integrate and more effective. He also says the adoption of automation in Southeast Asia is being hindered due to manufacturers’ limited knowledge on automation coupled with the high cost and time constraint associated with the production set-up. OnRobot, founded in 2015, is headquartered in Denmark. It provides plug & produce EOATs.

Industrial automation challenges/introduction

Historically, one of the biggest barriers to automation has been cost and time constraints associated with the production set-up. The procedure is usually performed by a team of robotics experts adept in programming languages and advanced engineering, subjects unfamiliar to most.

Demand for automation is flourishing from various manufacturing sectors leading to greater innovations in industrial robotics. With this trend, companies are prompted to adapt more and more intelligent tools that can help the production workforce with faster deployment and installation, saving their precious time on planning and strategy.

But not many businesses have been able to do so quickly because most are not ready to address collaborative applications with newer technologies. This is due to limited knowledge or resistance to adopting modern endof- arm tooling (EOAT) with collaborative robots (cobots).

Continuous technology transformation and the rise of collaborative applications in industrial automation have made robots easily deployable. Intelligent EOAT devices come with in-built features that can be programmed easily, enabling faster set-up. With EOAT, automation becomes more inclusive, delivering collaborative applications to meet modern automation needs.

Automation adoption rises in ASEAN

The ASEAN region’s combined GDP hit almost US$2.7 trillion in 2017, four times the value in 2000, clocking an average 5.3% yearly growth. ASEAN could become the world’s fourth largest economy by 2030 if this growth maintains.1 To achieve this, the region needs to leverage the opportunities presented by Industry 4.0 technologies. Adoption of these technologies remains slow in most countries however, with many manufacturers still relying on outdated processes.2

Singapore is spearheading the adoption of automation and robotics, recording the second highest industrial robot density globally at 658 robots per 10,000 employees.3 Malaysia and Thailand have also increased their focus on automation, encouraging greater use of robotics through the National Policy on Industry 4.0 (Industry4WRD) and the Thailand 4.0 strategy respectively.

This has led to an increase in cobot adoption and greater demand for collaborative applications. Coupled with the fast-changing nature of industries, this driving demand for modular and advanced EOAT.

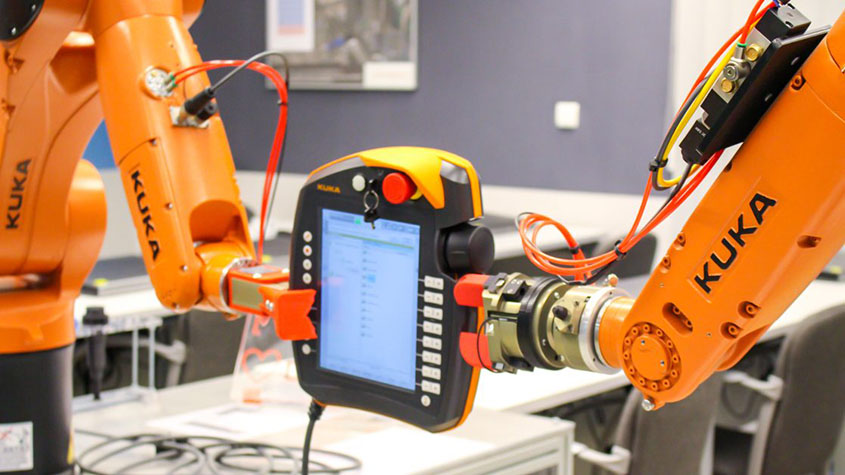

Easy and robust system integration with collaborative tools

System integrators have been of immense importance in robotics as they provide support with programming and outfitting processes. A robust system integration plan is not complete without the right EOAT devices. In fact, a major part of a plan focuses on picking the right end effectors such as grippers, sensors and tool changers that can be easily programmed with the robot. With more applications being collaborative in nature, system integrators believe that fitting appropriate tools around robots is becoming more crucial than robots alone. EOAT tools enable a two-way information exchange between the robot and the object. It makes installation simpler and easier, reducing setup time and effort drastically.

Smart, flexible and collaborative robotic accessories completely revolutionise the flow and quality of systems integration (SI).

Intelligent grippers, for instance, can collect and communicate crucial data to robots in real time to improve their accuracy and overall performance. Capable of safely passing products to human operators, these state-of-the-art grippers can essentially function as automated co-workers. For machine tending, dual grippers can operate up to 50% faster for computer numerical control (CNC) machine utilisation.

Intelligent EOATs benefit system integrators in many ways. Unlike dated homegrown technology, advanced EOATs can handle multiple tasks and varying projects, which saves time wasted on reprogramming and redeployment. Ready for easy integration out of the box, these tools can not only be implemented with ease, but also come with pre-programmed software packages that further quicken the installation process.

OnRobot ’s growing suite of cutting-edge EOATs and applications can work with robots across industries and manufacturers. The RG2-FT Gripper, with its built-in six-axis F/T Sensor fingertips and proximity sensor it can detect a product’s location even if it is not precisely positioned. This feature can be invaluable for tasks that require an item’s placement on or removal from conveyor belts. It is also ideal for precision assembly of electronics, automotive parts and other machinery.

The upshot of automation

When it comes to robotic automation, quality control is crucial for businesses because mishandled and otherwise ruined raw materials have real consequences for a company’s bottom line. Legacy tools that are either not smart enough and/or incapable of adapting to different products and environments may cause such wastage.

EOATS like OnRobot’s breakthrough HEX 6 axis F/T Sensor are designed to eradicate such issues. It provides accurate force and torque measurements along all six axes, resulting in precise control when it comes to difficult assembly, polishing, sanding or deburring jobs. Additionally, it has in-built software that can manage path recording, force control and special features for insertion tasks. This means reduced integration time for production lines.

With Industry 4.0, ASEAN countries are optimistic about kick-starting their industry transformation journey with smart automation driven by advanced EOAT. Through advanced features and innovative interfaces, EOAT can boost the labour market, accelerate productivity and solve automation challenges in numerous industries. ASEAN has the potential to capture productivity gains worth US$216 billion to US$627 billion through Industry 4.0.4

Breaking down barriers

In 2018, Enterprise Management Associates released a survey of more than 1,000 IT and business-related professionals at companies with more than 500 employees. Among other findings, only 4% of respondents said their company was “not as good as most” in terms of automation maturity; in comparison, 41% described their business as “very mature” or “state-of-the-art.”

Those businesses that do not explore new automated technologies may limit their growth potential and risk falling behind competitors. Integrating automation into processes can be difficult, but technological advances that make modern robotic tools and accessories easier to install, more compatible and more flexible have made it easier than ever before.

KraussMaffei showcases pioneering Additive Manufacturing solutions at formnext

precisionPrint stereolithography 3D printer show smultilaser-technology for series product…