Machinery & Technology at Fakuma Technologies to be showcased in Germany

To be held from 16-20 October 2018 in Friedrichshafen, Germany, Fakuma will have 1,800 exhibitors showcasing machinery and technology related to injection moulding, extrusion, thermoforming and 3D printing. Organiser PE Schall says the show this year, the 26th edition, is completely sold out.

Materials

- Ascend Performance Materials will showcase a new Vydyne PA66 grade for automotive lightweighting. The R433H is designed to reinforce down-gauged steel and aluminium used in vehicle body in white (BIW) structures, helping reduce weight. It is said to exhibit improved energy absorption over traditional glass-filled PA66, reducing noise, vibration and harshness (NVH) and absorbing impact energy from crashes. Ascend will also highlight its newly acquired manufacturing facility in Tilburg, Netherlands, having closed the buy of compounder Britannia Techno Polymer. It is Ascend’s first European manufacturing base.

- With sensors in the car being important in assisting the driver, German firm BASF offers its resistant PBT Ultradur HR and PA Ultramid EQ for sensitive electronic applications. For NVH, it provides solutions made from the microcellular polyurethane elastomer Cellasto as well as glass-fibre reinforced PA Ultramid and the Elastollan TPU for top mounts, spring seats and other chassis components.

- Germany’s Barlog Plastics will introduce its Kebaform XFA POM, a low-emission material for vehicle interior applications. It also boasts a significant reduction in formaldehyde, and meets current formaldehyde limits, even in unfavourable processing conditions (temperatures up to 220°C, with a residence time of several minutes).

- German firm Covestro will showcase a prototype automotive front module with a 3D, jointless and glasslike surface and without the classic radiator grille. The structure of the prototype consists of a film printed with a coloruful motif, such as the company logo, replacing the classic metal logo. This composite is then overmoulded with transparent Makrolon PC using film insert moulding technology (FIM). The flat surface and the depth effect of the PC create a glass-like 3D appearance. A transparent, scratch-resistant silicone hard-coating is also applied as the outermost layer. The structure can be made permeable to radar and LiDAR radiation, and also allows the integration of further functions like embedding heating wires for de-icing.

- Dow Performance Silicones will launch a new siliconebased slip additive for LDPE film that optimises form-fill-seal (FFS) packaging production. It will also showcase the Dow Corning HMB-1903 masterbatch, silicone-based, anti-squeak technology for automotive interior parts that reduces the coefficient of friction (COF) in PC/ABS components to minimise NVH.

- Together with the Fraunhofer Institute for Production Technology (IPT) and the Fraunhofer Institute for Laser Technology (ILT), IKV Plastics Processing Institute at RWTH Aachen University will present the latest injection-moulded and injection compressionmoulded optics, continuously produced optical film and optical materials and applications. At the heart of the presentation will be the production of a plastic freeform lens with micro-structured sections developed in cooperation with Innolite GmbH and Arburg.

- Germany’s FKuR will be presenting the injection moulding grade Bio-Flex S 7514. With improved flowability and heat resistance, it is a PLA-based (75% content) compound, which has been optimised for efficient processing. Thanks to its good flowability (MFR =27 g/10 minute), it is also suitable for use in multi-cavity moulds and the production of parts with longer flow paths. The high heat resistance (Vicat A = 110°C), which is achieved without a hot tool, allows for shorter cycle times. It can be used in catering applications such as cutlery.

- Germany’s Kraiburg TPE will be highlighting two Thermolast materials for automotive interior and consumer applications. The new Thermolast K series FG/SF comprises several compounds in Shore A hardness range between 50-80 with surface properties for automotive interior parts, including adhesion to PP and good abrasion resistance. In the Thermolast K series for food contact, FC/AD/PA, the compounds boast adhesion to PAs. Naturally-coloured, these are available in hardness degrees ranging from 40-80 Shore A.

- Speciality materials firm Lanxess will have new PA6, PA66 and PBT compounds with a high level of transparency with laser light from the near-infrared range, especially for complex formed components that are manufactured in series by laser transmission welding. Also new is a halogen-free flame-retardant laser-light-transparent Durethan AKV30FN04LT, a PA66 achieving the best classification of V-0 (0.4 mm) inflammability testing pursuant to the US UL 94 standard. Adding on to this is a new glass fibrereinforced PBT compound that achieves improved results in glow-wire tests on finished components.

- Polyplastics has latest POM resin grades with low-VOC emissions for the production of automotive interiors, to meet the latest regulations governing the

concentration of VOCs in interiors. It will also highlight its new Durafide PPS grade, which delivers improved heat-shock resistance for a range of automotive applications, plus the viability of PPS for bump-off moulding of automotive engine cooling systems. It results in an undercut that “bumps” in two directions and ejects from the mould without using a sliding structure. The parting line (mould lip) goes away, allowing for a burr-less mould. The company has also developed Duranex 457EV, an unfilled, high-impact PBT that satisfies the UL 2251 standard for electrical/electronics and automotive applications.

concentration of VOCs in interiors. It will also highlight its new Durafide PPS grade, which delivers improved heat-shock resistance for a range of automotive applications, plus the viability of PPS for bump-off moulding of automotive engine cooling systems. It results in an undercut that “bumps” in two directions and ejects from the mould without using a sliding structure. The parting line (mould lip) goes away, allowing for a burr-less mould. The company has also developed Duranex 457EV, an unfilled, high-impact PBT that satisfies the UL 2251 standard for electrical/electronics and automotive applications.

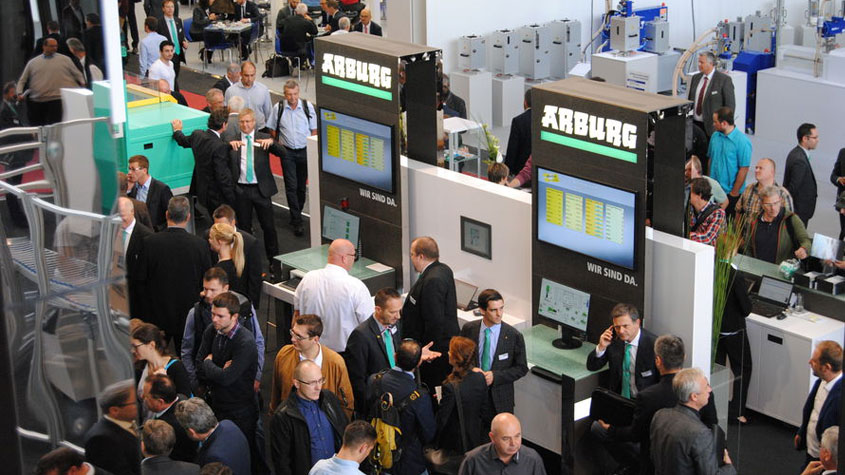

Machinery

- Under the theme of the “Road to Digitalisation”, Germany’s Arburg will have different stations pointing the way towards efficient plastic parts production. These include six new Arburg assistance packages, the benefits of augmented reality in service and the launch of its new customer portal. In digital transformation, it will have”4. set-up” that supports machine operators with set-up and parameter entry; “4.start-stop” for simplifying production start-up, with lesser number of start-up parts and higher production capacity; “4.optimisation” designed for product optimisations aimed at enhancing part quality and reducing unit costs; “4.production” to give experienced operators flexibility and freedom when programming functions; “4.monitoring” for process and quality monitoring and seamless documentation and “4.service” to allow direct access to the machine control system and via online support, thereby increasing machine availability.

- The six injection moulding exhibits in mint green, light grey and dark grey will also provide for a new look at its stand. This new colour scheme will be used for all its Allrounders from the start of 2019. For the first time, Arburg is showing the Allrounder 820H in its new design in a packaging version. The exhibit shown will produce four thin-wall IML containers with a capacity of 500 ml in a cycle time of around 3.8 seconds.

- Also new is the Arburg Turnkey Control Module

(ATCM) for a complex turnkey system. Plus, it will show a practical example of Industry 4.0 on elastic tension belt production and LSR moulding of micro components on an electric Allrounder 270A. The potential of the Freeformer and Arburg Plastic Freeforming (APF) will also be on view.

(ATCM) for a complex turnkey system. Plus, it will show a practical example of Industry 4.0 on elastic tension belt production and LSR moulding of micro components on an electric Allrounder 270A. The potential of the Freeformer and Arburg Plastic Freeforming (APF) will also be on view. - Arburg will present its range of training courses and services using a hydraulic Allrounder 370S – for example the Arburg Remote Service ARS for secure online support. There will also be an example on the subject of predictive maintenance, which is becoming increasingly important as machines and components are digitally integrated.

- Production management of injection moulding is a complex activity that combines organisational planning and supervision. Taiwanese machine maker FCS Group first announced the iMF 4.0 (Intelligent ManuFactory) smart manufacturing system this year, and set up a demonstration factory at its Tainan headquarters to provide real-world solution for the industry 4.0 applications that are needed by injection moulding industry customers.

- The traditional injection moulding production management is based on handwritten record statistics, which is easy to derive many risks and cannot

immediately respond to the problem, therefore the effect of production management improvement cannot be highlighted. The iMF 4.0 system is based on the cycle time management and introduces the concept of mould, machine and material management; and OPC international communication protocol to achieve instant display of overall equipment efficiency (OEE) information and abnormal message statistics.

immediately respond to the problem, therefore the effect of production management improvement cannot be highlighted. The iMF 4.0 system is based on the cycle time management and introduces the concept of mould, machine and material management; and OPC international communication protocol to achieve instant display of overall equipment efficiency (OEE) information and abnormal message statistics. - The production manager can promptly grasp the production status and rapidly achieve the purpose of abnormal production counter-measures, and Industry 4.0 mobile computing, analysis and optimisation, to improve efficiency and reduce waste, and achieve the management purpose of rapid production of abnormal measures. iMF4.0 can also be used to monitor the state of equipment in the global production line through synchronisation, to achieve the concept of off-site production management.

- With Over 40 years of technological developments and innovations, the overall performance of FCS machine has reached high levels of stability and reliability. Meanwhile, FCS offers optimised designs with differentiated features for the product characteristics of each specific industry. The company says its newly launched iMF4.0 system has seen high sales after its introduction at the Taipeiplas exhibition in August.

- Austria’s Engel will make three premieres of machinery, all running in one exhibit: a larger 120-tonne all-electric tiebarless machine; a fully automated system for fast switching of mould inserts for small lot production; and expanded functionality of its e-flomo electronic temperature-control water manifold, which contributes to achieving shorter set-up times. Lot sizes of less than 1,000 present a special challenge in injection moulding. In order to economically realise a large number of variations, moulds with interchangeable inserts are often used. The system solution presented allows for a fully automated switch of the mould inserts within just one minute. Engel’s e-motion 170/120 TL machine will be equipped with a mould that includes the fast-switch mechanism patented by Braunform. The cell addresses the needs of customers who produce articles similar to each other in small lot sizes or with a high degree of variation.

- At Dr Boy’s booth a new, large Boy 125E will make its world premiere. The two-component machine features

a width of 470 mm between the tie bars instead of the previous of 430 mm. In addition, the maximum platen distance has been extended to 825 mm as standard for more space, for example when using rotary plates. A further advantage is a 25% higher clamping force, with a clamping force of 1,250 kN now available from the typically small machine maker. It will show a two-component application, in combination with a Boy 2C S, cups made of NAS30 are first injected and then partially over-moulded in a second component by the additional injection unit in the same mould. The removal handling LR5 repositions the premoulded cups in the mould, removes the finished twocomponent parts and places them on a conveyor belt in the protective housing of the automation cell.

a width of 470 mm between the tie bars instead of the previous of 430 mm. In addition, the maximum platen distance has been extended to 825 mm as standard for more space, for example when using rotary plates. A further advantage is a 25% higher clamping force, with a clamping force of 1,250 kN now available from the typically small machine maker. It will show a two-component application, in combination with a Boy 2C S, cups made of NAS30 are first injected and then partially over-moulded in a second component by the additional injection unit in the same mould. The removal handling LR5 repositions the premoulded cups in the mould, removes the finished twocomponent parts and places them on a conveyor belt in the protective housing of the automation cell. - Germany’s KraussMaffei will show two new all-electric presses. A PX320 model will exhibit a patent-pending technology developed by Leonhard Kurz of Germany. This system allows two independent heat-transfer foils to be

transported reel-to-reel through a two-cavity mould. The two in-mould decorating (IMD) films transfer the printed decoration to the plastic part under the influence of heat and pressure during moulding, with a servo-controlled positioning unit for each IMD film, which is integrated into the PX machine. The system uses sensors beside the films to read registration marks on the films for positioning accuracy within 0.01 mm. The double-IMD process will be supplemented with IML to produce a 10-in. HMI (human-machine interface) display with integrated electronics, black decorative frame, and scratchproof coating. Meanwhile, KM will also demonstrate its new PX25 model producing a 0.15 g LSR sealing ring with an intricate undercut, using a 12-mm screw, complemented with a spring-loaded check valve, in a 14 second-cycle.

transported reel-to-reel through a two-cavity mould. The two in-mould decorating (IMD) films transfer the printed decoration to the plastic part under the influence of heat and pressure during moulding, with a servo-controlled positioning unit for each IMD film, which is integrated into the PX machine. The system uses sensors beside the films to read registration marks on the films for positioning accuracy within 0.01 mm. The double-IMD process will be supplemented with IML to produce a 10-in. HMI (human-machine interface) display with integrated electronics, black decorative frame, and scratchproof coating. Meanwhile, KM will also demonstrate its new PX25 model producing a 0.15 g LSR sealing ring with an intricate undercut, using a 12-mm screw, complemented with a spring-loaded check valve, in a 14 second-cycle. - US firm Milacron will demonstrate the Imfluxenabled low-pressure moulding process developed by

multinational Procter and Gamble and marketed by its new Imflux subsidiary. The technology uses a low, consistent pressure to fill the mould while packing the melt and cooling the mould, thus achieving up to 50% faster cycles, reduced part weight, lower stress, less warpage and fewer sinks. Milacron says the process can be particularly advantageous for processing sensitive biomaterials. At Fakuma, a technical part on an allelectric Elektron EVO 155 press will be running with a two-cavity Imflux mould. The cell will show off a new addition of an adaptive process-control module to Milacron’s M-Powered package of IoT solutions. This module enables the Imflux process with a stable melt pressure and a variable filling rate that adapts to the part geometry.

multinational Procter and Gamble and marketed by its new Imflux subsidiary. The technology uses a low, consistent pressure to fill the mould while packing the melt and cooling the mould, thus achieving up to 50% faster cycles, reduced part weight, lower stress, less warpage and fewer sinks. Milacron says the process can be particularly advantageous for processing sensitive biomaterials. At Fakuma, a technical part on an allelectric Elektron EVO 155 press will be running with a two-cavity Imflux mould. The cell will show off a new addition of an adaptive process-control module to Milacron’s M-Powered package of IoT solutions. This module enables the Imflux process with a stable melt pressure and a variable filling rate that adapts to the part geometry. - KraussMaffei member company Netstal will showcase its smallest model, Elios 4500-2900, producing 12-cm PP plant pots in a six-cavity mould from Glaroform. And to spice things up, the pots will be moulded in various colours with UCC providing the colour masterbatches. A Brink Automation robot will remove and stack the finished pots, in a cycle time of 3 seconds. The flow path/ wall thickness ratio is 331:1.

- Japan’s Fanuc will be exhibiting the biggest of its allelectric Roboshot machines, the new S450iA with 4500 kN clamping force, a tie bar distance of 920 mm by 920 mm, a clamping stroke of 900 mm, a 1,300 mm by 1,300 mm platen size and a maximum die height of 1,000 mm. It also features a torque plasticise control – Precise Metering Control (PMC) 2&3 – as well as backflow monitor and AI mould/ejector protection.

- Germany’s Sumitomo (SHI) Demag Plastics Machinery will debut its compact high-speed IntElect S, the new allelectric machine series for high-speed parts. An IntElect S 130/520-450 will be shown moulding pipettes, in a cell with a compact system developed by automation specialist Waldorf Technik comprising 100% visual inspection for sorting the pipettes into the appropriate racks. Sumitomo Demag will now offer both standard and high-speed machines with all-electric drives.

- Having shown a prototype of its new VPower machine at its tenth anniversary in June, Austria’s

Wittmann Battenfeld will present it at the show. The servoelectric-powered rotary table as standard allows the injection unit to be converted from vertical to horizontal and vice versa even after commissioning. The absence of a central tie-bar enables central media supply from below through the rotary table or via the installation of a compact rotary manifold. The machine is suited for the integration of automation systems with insert feeding and finished part removal functions.

Wittmann Battenfeld will present it at the show. The servoelectric-powered rotary table as standard allows the injection unit to be converted from vertical to horizontal and vice versa even after commissioning. The absence of a central tie-bar enables central media supply from below through the rotary table or via the installation of a compact rotary manifold. The machine is suited for the integration of automation systems with insert feeding and finished part removal functions. - Member of the Brückner Group Austria-based Kiefel Packaging will display its Blowliner single-stage servomotor-driven injection blow moulding machine, available in three sizes. It features a vertical hydraulic Engel machine with up to 400-tonne clamping force and a clamping surface of up to 800 x 1,000 mm for (multilayer) preform production and a stretch-blow unit with a 40-tonne clamping force. Available with one to four-row blow moulds, each series of cavities has its own pre and main blow-off valve, so that the blow pressure can be set individually, making it possible to run different products using one tool.

Auxiliaries/Tooling/Robots

- Austrian recycling equipment firm Erema, its business unit Powerfil and sister company Pure Loop will be exhibiting in one booth. The exhibits include Erema’s recycling and compounding technology Corema; its anti-odour ReFresher (together with Intarema TVEplus machine) technology for odour-optimised premium recycled pellets directly from contaminated postconsumer material; proprietary QualityOn software for continuous quality monitoring of colour and MVR values; and Re360, its Manufacturing Execution System for real-time production and machine data. Powerfil will be showing its filter systems that are also suitable for existing extruders, while Pure Loop is presenting the ISEC evo, an integrated shredder-extruder combination.

- For the first time at Fakuma, Swiss firm Maag will be sharing a stand with filter manufacturer Ettlinger, which joined the group in January this year. Maag will be presenting a Primo 200 E model pelletiser from its WSG dry-cut strand pelletising systems for the production of cylindrical or micro-pellets. With a 200 mm draw-in width, it is designed for speeds up to 120 m/minute and a maximum throughput rate of 1,500 kg/hour. Its Pearlo 160 forms part of a new family of underwater pelletising systems, developed for the production of spherical plastic pellets, combining technologies from sister companies Gala and Automatik. Meanwhile Ettlinger will present its Eco 200 melt filter, designed for free-flowing materials such as PET and PA.

- Italy’s Moretto is displaying its Efficiency 4.0 supervisory and management system. It also has a new compact DPK loss-in weight dosing unit, while for extrusion

its subsidiary Contex has a new DBK Gramixo batch dosing unit with continuous loss-in-weight control of extruder feeding. Also new are three types of hoppers: stainless-steel TM standard hoppers; TMC hoppers for hot, dried materials, and clear acrylic-TMK Krystal hoppers. In addition, several new products for mould cooling and temperature control will presented, including TeKo chillers/ temperature-controllers, dual-zone units with both heating and cooling capability, as well as integrated free cooling. Also new is the the DS mould dryer designed to prevent condensation or “sweating” in the mould area.

its subsidiary Contex has a new DBK Gramixo batch dosing unit with continuous loss-in-weight control of extruder feeding. Also new are three types of hoppers: stainless-steel TM standard hoppers; TMC hoppers for hot, dried materials, and clear acrylic-TMK Krystal hoppers. In addition, several new products for mould cooling and temperature control will presented, including TeKo chillers/ temperature-controllers, dual-zone units with both heating and cooling capability, as well as integrated free cooling. Also new is the the DS mould dryer designed to prevent condensation or “sweating” in the mould area. - Aquatech, a part of Italian auxiliary firm Piovan, will present its new Easytherm mould-temperature-control

unit (TCU), with redesigned controls. The latter include a new tilted, 4.2-in. display with high brightness and strong colour contrast to ensure easy readability in low-light conditions. Easytherm incorporates the OPC-UA communication protocol, making it ready for communication with machines from different suppliers in Industry 4.0 environments with open standards. It also can be used with Piovan’s Winfactory 4.0 supervisory software.

unit (TCU), with redesigned controls. The latter include a new tilted, 4.2-in. display with high brightness and strong colour contrast to ensure easy readability in low-light conditions. Easytherm incorporates the OPC-UA communication protocol, making it ready for communication with machines from different suppliers in Industry 4.0 environments with open standards. It also can be used with Piovan’s Winfactory 4.0 supervisory software. - Automated IML solutions provider Beck Automation will present a compact IML system for yoghurt pots with a full wrap label. The system boasts a seamlessly integrated Vision System for optical quality control by Intravis, consisting of the IML Watcher, featuring several cameras and specific lighting units, enabling errors typical for the IML process to be detected.

- Coperion and Coperion K-Tron will present the ZS-B twin-screw side feeder for feeding of fillers and additives in powder or pellet form or cut glass fibres into the process section of the twin-screw extruder. It is equipped with the patented Feed Enhancement Technology (FET) that increases the material intake capacity in the processing of feed limited products by up to three times. For improved feeding accuracy of loss-in-weight feeders, Coperion K-Tron will be presenting its EPC electronic pressure compensation system. The main advantages of the new system include improved accuracy and reliability as well as lower initial cost and easier installation compared to traditional mechanical pressure compensation systems.

- Brabender Technologies will exhibit its new Easy Change version of the FlexWall Plus all-purpose loss-in weight feeder, which features lateral massage paddles that gently stir the bulk material and ensure mass flow without degradation. Different replaceable screw profiles are used depending on the bulk material handled and the performance range required. It also includes the hopper, screw, screw tube and housing as a single unit. Quick-release clamps secure this unit to the chassis and drive mechanism and only need to be released to enable any residual bulk material to be removed.

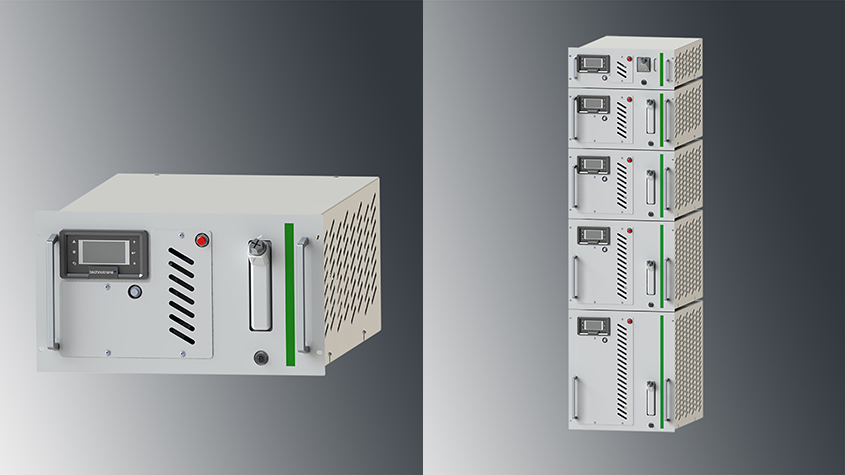

- ProTec Polymer Processing is premiering its Somos Perfoamer, which implements the Plastinum Foam Injection

Moulding process presented by Kunststoff-Institut Lüdenscheid and Linde in 2017 on an industrial scale. It includes all the components for drying and temperature adjusting polymer pellets, loading them with CO2 under pressure and then feeding them to any desired machine, which generally requires no modification. Live foaming demonstrations of the Perfoamer will be shown on an Engel e-victory 310/80 machine producing 42 g-bottle openers in a variety of polymers.

Moulding process presented by Kunststoff-Institut Lüdenscheid and Linde in 2017 on an industrial scale. It includes all the components for drying and temperature adjusting polymer pellets, loading them with CO2 under pressure and then feeding them to any desired machine, which generally requires no modification. Live foaming demonstrations of the Perfoamer will be shown on an Engel e-victory 310/80 machine producing 42 g-bottle openers in a variety of polymers. - Tool maker Hasco is introducing a new hardened and tempered steel – steel 1.2714HH – with dimensional stability and wear resistance, good polishing and etching properties, and optimum thermal conductivity. Another highlight is the screw-in Vario Shot nozzle that allows ready-to-assemble systems to be designed and manufactured according to customers’ requirements.

- HRSflow will be demonstrating its Flexflow technology of servoelectric-driven valve gate solutions based on examples ranging from technical automotive parts to a thinwall laptop housing and an ultra-light tool box made of microcellular foam. The latter is based on the FoamPro foaming process from development partner Yizumi, and a Flexflow triple-nozzle hot runner system from HRSflow with back-injection.

- French robot maker Sepro is showing a total of 22 robots, including eight at its own stand. It will have three examples from its popular Success range of threeaxis, general-purpose robots for 20-700-tonne machines, operating together with an S5 picker, with a three-axis design similar to Success. Sepro will also feature its latest controls including OptiCycle, a plug-in developed in open collaboration with a key customer to automate cycle optimisation, and Live Support, an app that links customers with troubleshooting assistance. Both function with the Sepro Visual control platform on new and existing robots.

Chinese economy to grow over 6.5 pct in 2018, 2019: report

BEIJING, March 1 (Xinhua) — China’s economy will grow by over 6.5 percent this…